MENU

GB | GBP

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

- LabDays 2025

- ASIA LABEX: The Lab Show 2025

-

-

-

-

- Forum Labo 2025

- Advanced Therapies Week (ATW) 2025

- SLAS Europe 2025

- Bioprocessing Summit Europe 2025

- Medlab Middle East 2025

- SLAS International 2025

- Biologics World Nordics 2025

- ASIA LABEX: The Lab Show 2025

- BioProcess International Europe 2025

- ISEV 2025

- Future Labs Live 2025

- DataHow Symposium 2025

- Cell 2025

- LabDays 2025

- ASIA LABEX: The Lab Show 2025

GB | GBP

-

- Benchtop Centrifuges

- Floor-Standing Centrifuges

- Refrigerated Centrifuges

- Microcentrifuges

- Multipurpose Centrifuges

- High-Speed Centrifuges

- Ultracentrifuges

- Concentrator

- IVD Products

- High-Speed and Ultracentrifuge Consumables

- Centrifuge Tubes

- Centrifuge Plates

- Device Management Software

- Sample and Information Management

-

- All Pipettes, Dispensers & Automated Liquid Handlers

- Mechanical Pipettes

- Electronic Pipettes

- Multi-Channel Pipettes

- Positive Displacement Pipettes & Dispensers

- Automated Pipetting

- Bottle-Top Dispensers

- Pipette Controllers

- Pipette Tips

- Automation Consumables

- Dispenser & Pipette Accessories

- Automation Accessories

- Dispenser & Pipette Services

No results found

Search Suggestions

Centrifuge Safety

Lab Academy

- Cell Biology

- Centrifugation

- Lab Routine

- Centrifuges & Rotors

- Essay

Imbalances

What causes an imbalance?

Rotors spin very rapidly and generate extreme forces. It’s therefore crucial to properly balance rotors during runs, especially when rotors are only partially loaded with tubes or plates. Balancing is always important (in order to not decrease the lifetime of the rotor), but especially so when centrifuging at higher speeds. Despite your efforts, however, imbalance errors caused by unbalanced sample loads can occur.

What risks do I face when exposed to an imbalanced load?

Incorrect loading can reduce the lifetime of the rotor, and uncontrolled, heavy vibration can lead to permanently damaging the centrifuge. More importantly, however, an imbalanced load can injure you or someone else. In the worst case, an imbalance can lead to a rotor crash.Read more

Read less

Does my centrifuge realize the load is imbalanced?

Many centrifuges have auto-imbalance detection and will decelerate or automatically shut off if they sense an excessively unbalanced load (sensors are specifically built into the centrifuge for this purpose). Mostly bigger models (large benchtop and floor-standing centrifuges as well as ultracentrifuges) have this option. Smaller benchtop models, on the other hand, do not create strong enough forces to cause harmful imbalances; with these models, you would just notice a slight vibration and/or a higher noise level. Be aware that auto-imbalance detection does not automatically compensate for an unbalanced load.Read more

Read less

What do I have to do if an imbalance error occurs?

If the centrifuge begins to shake or wobble, it is off-balance and you should stop it immediately. A little vibration is normal, but excessive amounts can mean danger. Once you have stopped the centrifuge, first double check to see if you have correctly balanced the tubes or plates in the rotor or buckets. If they are correctly balanced and the wobbling still occurs, contact the manufacturer or dealer to get the unit serviced. Do not continue to run a centrifuge that visibly wobbles when the rotor is spinning.

How do I avoid centrifuge imbalances in the first place?

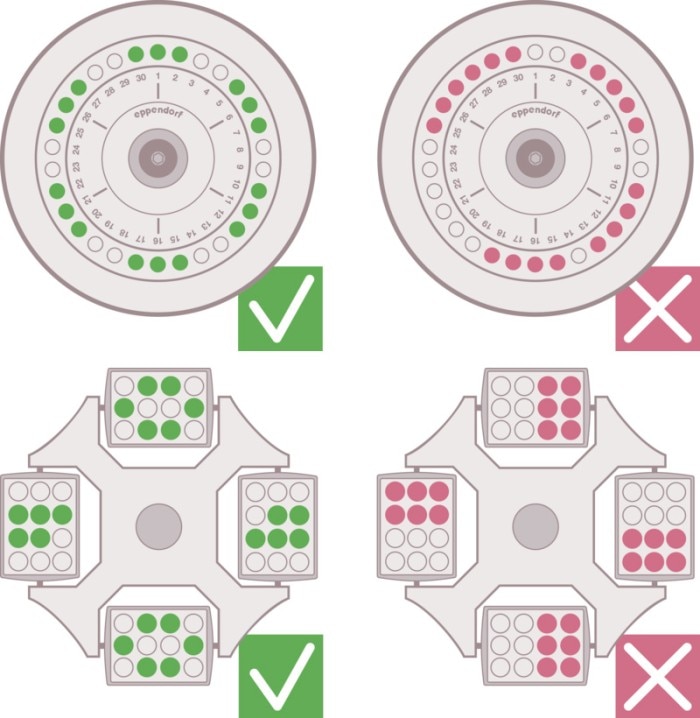

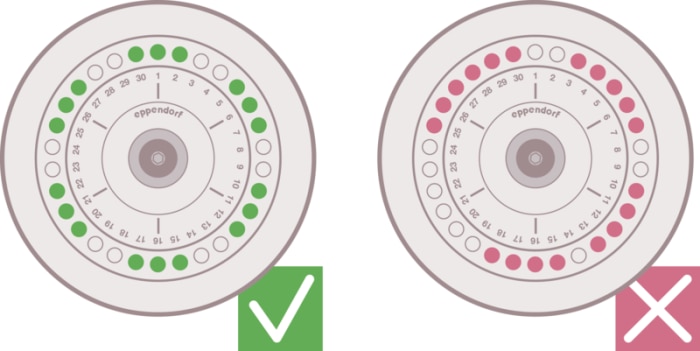

Ensure that your work surface is level and firm. Do not use the centrifuge on an uneven or slanted work surface.At high speeds, a centrifuge can easily become unbalanced if equal masses are not located opposite each other in the rotor:

For fixed-angle rotors, balance your tubes according to their weight. Load the rotor symmetrically and ensure the opposing tube is not only the same type of tube, but that it is also filled with the same mass.

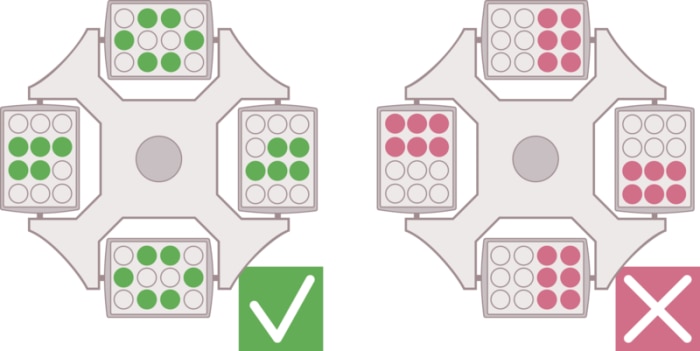

If the number of tubes with samples is uneven, counterbalance using water in an additional tube. Remember to balance the mass (weight) of the tubes, not the volume (size). Weigh the tube with your sample and record the mass. If you are spinning more than two tubes, only the tubes directly opposite each other have to be equal in mass.For swing-out rotors, always load all rotor positions with buckets (incomplete loading of the rotor may reduce the lifetime of the rotor). The weight of the maximum load or maximum weight of the completely loaded bucket is specified (weight class) on the buckets. Do not exceed this weight. When loading the buckets, make sure the tubes or plates are placed symmetrically.Always check to see that the buckets swing out smoothly. If they do not, clean the pivots and grooves and apply grease.

Read more

Read less

Loading

- Make sure the tubes you’re using have been specified for use with your centrifuge rotor. If necessary, support the tubes with adapters and check to see that the tube length allows the buckets to swing out to a horizontal position. When using aerosol-tight buckets, check to see that the tube length fits with the lid. Some centrifuge suppliers offer special rotors dedicated for use in the centrifugation of spin columns without risk of tearing off the tube lids. Using a different rotor than recommended by the manufacturer can easily lead to spills within the centrifuge, which may result in the formation of aerosol. This can be dangerous to your health and the environment.

- Inspect centrifuge bottles and tubes or plates for cracks before use. Because a centrifuge can spin at such high speeds, a liquid sample can easily become an aerosol if it is not properly contained. Cracked tubes can fracture at high speeds or, at the very least, leak the sample into the rotor. As a last step, be sure to securely fasten the rotor lid provided with the centrifuge or the aerosol-tight cap of the buckets.

Read more

Read less

- When working with a swing-bucket rotor that has not been completely loaded, position the tubes within the buckets in a pattern that results in the rotor pivots being evenly stressed.

- Clearly label all your tubes for identification. You may know how you placed your tubes in the centrifuge before they started spinning, but at the end of the spin you will not be able to tell them apart. If you have a tube you’re using for balance, be sure you label it as such. It is best to label the tube directly instead of using a sticker. A sticker can fall off during the spin, making identification difficult.

Load swing-bucket rotor evenly

- Clearly label all your tubes for identification. You may know how you placed your tubes in the centrifuge before they started spinning, but at the end of the spin you will not be able to tell them apart. If you have a tube you’re using for balance, be sure you label it as such. It is best to label the tube directly instead of using a sticker. A sticker can fall off during the spin, making identification difficult.

Label your tubes for identification

- Wipe the outside of the tube with disinfectant before placing it in the centrifuge. Wiping the tube is particularly important if you are working with a biohazardous material. You want to limit any possible spills or aerosol formation with your sample. The best prevention is to wipe down the tube with a proper disinfectant before the spin begins.

- Ensure you have not exceeded the maximum filling quantity for the sample containers specified by the manufacturer.

- Fill the sample containers outside the centrifuge. No liquid should be allowed to enter the centrifuging chamber during filling.

Read more

Read less

- For swing-out rotors, all buckets should be of equal weight when loaded. For fixed angle rotors, balance your tubes according to their weight.

Load rotor symmetrically

- The rotor must be loaded symmetrically: This means opposing tubes should be the same type of tube and filled with the same mass. If you are spinning more than two tubes, only the tubes directly opposite each other have to be equal in mass. At high speeds, a centrifuge can easily become unbalanced if equal masses aren’t located opposite each other in the rotor.

Automatic rotor recognition

Many centrifuges (especially multipurpose benchtop centrifuges) have automatic rotor recognition. This feature detects a newly inserted rotor and automatically limits g-force (rcf)/speed (rpm) to the rotor’s maximum permissible value. In other words, automatic rotor recognition prevents a rotor from being used at a higher speed than it was designed for. However, smaller centrifuges with a limited selection of rotors, in particular, and similar types of rotors often do not have rotor recognition. In these cases, all rotors have been designed to work at the maximum speed of the centrifuge. The Eppendorf Centrifuge 5424 R is one example of this type of centrifuge: All of its rotors are designed to spin up to 15,000 rpm, thus no automatic rotor recognition is needed for this centrifuge.Handling of Hazardous Material

Read more

Read less